An oven that won't bake may have many causes. A customer may complain that only the top of her food is cooking or that the oven get warm but not hot. This symtom is causes by the fact that most ovens turn on both the bake and broil element during preheat to hasten the process but the broil element cycles off once the cavity reaches about 200F. Thus an oven with a bad bake element will get somewhat hot from the broil element preheat. Of course this element soon cycles off and the set point is never reached.

1. By far the most common cause is a bad bake element. Any hole or break in a bake (any element) is visual confirmation of a failure. Some fail with striking fireworks display. With no visual evidence an ohms test is necessary. Turn off the breaker first! Power is always on any 220 vac device even if the oven if off. Remove at least one supply lead and test the element for continuity. Replace if necesssary.

2. Bad connections or wiring behind the element. As stated, shut off the breaker, remove the element for a wiring check. Bad wiring or connectors must be replaced in addition to a new element. Don't try to make a new connection to an old, cooked, overheated element. It will not last. Be very cautious moving the wires or they will disappear from sight and you will need to pull the oven to retrieve them. Trick of the Trade: Always use high temperature spade ends.

Burned Off Spade Connector

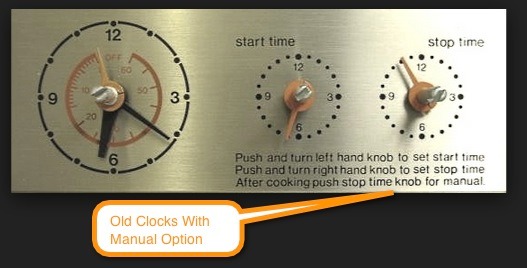

3. Improper control settings. Automatic clocks and self cleaning locks can easily be at fault. Play with everything. Try the broil element and the second oven (if there is one) to confirm that you do have 220 vac and determine how basic your problem is. With 220 vac confirmed you know your problem is within the bake circuit and not all the 220 vac circuits.

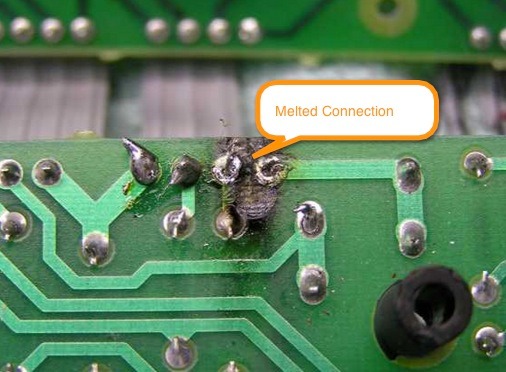

4. Bad ERC (electronic range control), thermostat, or relay board. With the power off a visual inspection of these components will often uncover a damaged area. Wiring only fails at connection points never within a harness. If a careful inspection does not uncover anything, the problem is likely within the ERC and most often the relay or connections to the relay. Confirmation means tracing the 220vac through the oven circuit, a difficult task.

Damaged Computer Board

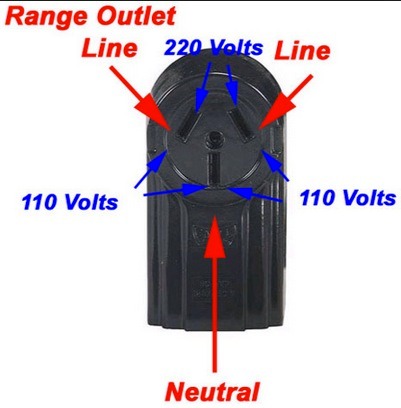

5. A break in one side of the 220vac within the oven cord connection box, outlet, or breaker panel. A break in only one side of the supply will still provide 110vac for the ERC display circuit. A half bad breaker can be at fault. Confirm 220vac coming into the oven.

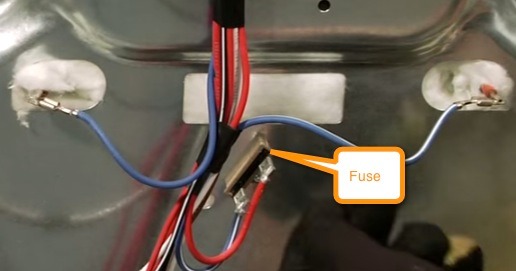

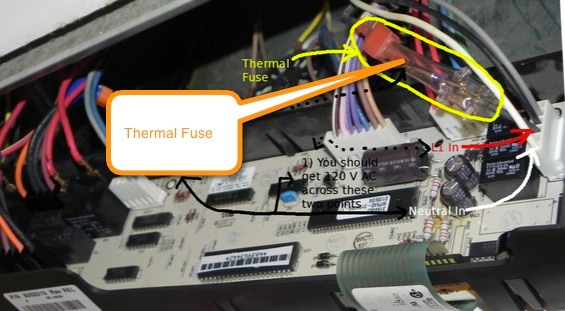

6. Newer designs now incorporate thermal fuses (non-resettable) screwed to the top on back of oven cavities and behind the console. This is common on Whirlpool designs. A blown thermal will halt both bake and broil.

Whirlpool Thermal Fuse

Electrolux Fuse

Whirlpool also has an inline thermal, right behind the board, that shuts down the entire ERC. It is enclosed in a small plastic sleeve.

7. On very old designs, prior to ERC's, bake and broil power were controlled by both a selector switch and a thermostat. Ideally, it is possible to trace a break in power, ie the failure to one or the other. The thermostat was more likely the culprit but both components were suspect because both carry the element current. However schematics are seldom available making tracing nearly impossible. The simplest solution, that I adopted years ago, was to order and replace both. The main expense is labor anyway and replacing both makes a first class repair.

.